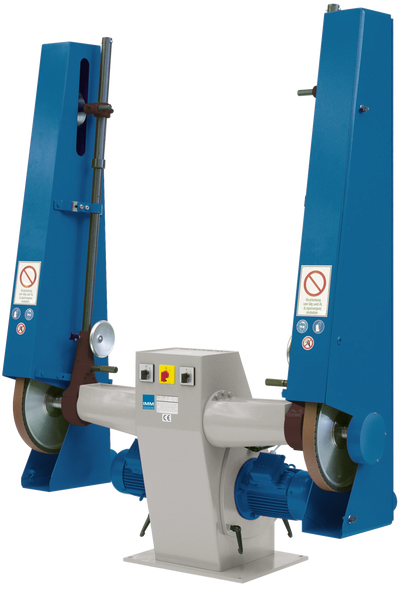

72780 belt grinder and polisher

Industrial belt grinding and polishing machine

The 72780 series is a heavy-duty design abrasive backstand belt grinding and polishing machine for multi-purpose applications. It can be configured with motor rating per spindle from 2.2 to 7.5 kW and is therefore ideal for industrial applications with high stock removal whilst minimizing vibration exposure.

Due to its double-sided design with optional combination of belt grinding and polishing, only belt grinding or only polishing, the 72780 series is a versatile belt grinder machine. Thanks to its robust, low-vibration design, it guarantees a long service life and precise work without shatter marks. The use of heavy cast iron components and welded machine base make it the most durable and strongest belt sander and buffing/polishing jack in the market. The 72780 series has the lowest vibration values ever recorded in any backstand grinder. Standard sanding belts with a length of 3,500 or 4,000 mm and a maximum width of 100 mm can be used on the machine. The maximum contact wheel dimensions are 450 x 100 mm with a bore of 35 mm. Max. polishing wheel diameter is 500 mm, with special covers up to 1.000 mm.

72780 examples & details

72780 with one side for belt grinding and sanding and other side for the use with polishing wheels, brushes and satinizing wheels.

72780 polishing machine configured with both sides for buffing and polishing.

72780 for wet belt grinding and sanding. Collection container for fetching coolant to distribute to gravity belt filter and recirculate. Ideal for belt polishing, finishing and grinding knifes and implants. Also recommendable for polishing titanium work pieces.

72780 with automated feed system for precision belt polishing and finishing of world-famous writing instruments. Luxury ballpoint and ink pen cap and barrel polishing.

Double ended 72780 polishing jack for polishing wheels up to 1.000 mm in diameter. With frequency converter for variable speeds.

Short video walk around 72780 double ended polishing jack for polishing wheels up to 1.000 mm in diameter.