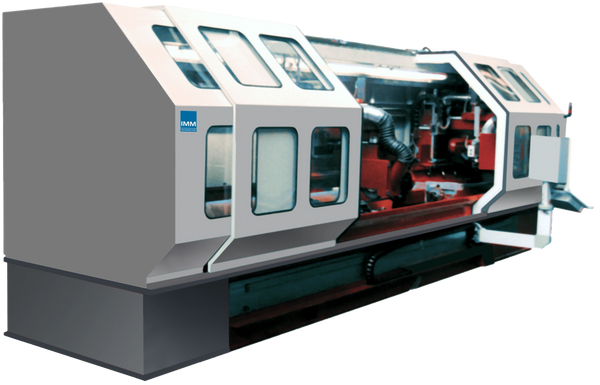

SIGMA CNC belt grinding and polishing machine

CNC-controlled belt grinding and polishing machine for extrusion screws and rotors type sigma with one working head for belt grinding of the worm pitches and the flanks of extrusion screws. Type sigma SP with 2 working heads for fully automatic belt grinding and the following polishing operation in one common cycle. The benefits of automated belt grinding and polishing screws, moineau rotors (mud motors) and stator cores are upstream savings by balancing processes.

• NC-feed units in X- and Z- direction

• NC-rotational unit (C-axis)

• NC-control SINUMERIK 840 D for 4 axes (sigma S) or 7 axes (sigma SP)

• Moveable tailstock

• Pneumatic tailstock quill with rotating centre

• Moveable steadyrest for the support of long, flexible extrusion screws

• High pressure polishing paste spraying equipment

• Automatic central lubrication

• Wet grinding equipment

• Dust exhaust pipes with sockets at the ceiling for connection to external

exhaust unit

• Complete machine enclosure

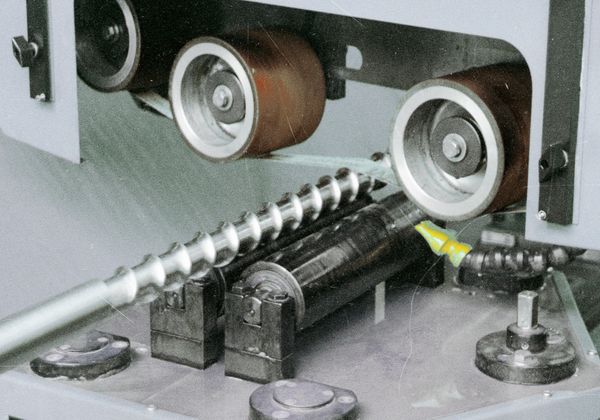

The belt head of the SIGMA CNC belt grinding and polishing machine is designed for quick-change contact wheel and slack belt attachments. Setting for slack belt grinding/polishing or belt grinding extrusion screws directly on the contact wheel is possible.

Angle settings allow belt polishing up the flanges and side walls of extrusion screws using flexible abrasive belts.

The processing heads can be fitted with polishing wheels for mirror finish buffing of extrusion screws, mud motor rotors (moineau rotors) and stator cores.

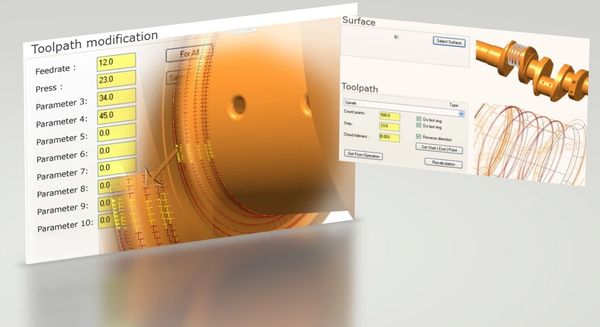

Auto polishing and finishing of all common extrusion screws.

CAD/CAM software for generating NC programs for polishing and finishing extrusion screws including machine simulation for collision control. Perfect for the SIGMA CNC belt grinding and polishing machine.