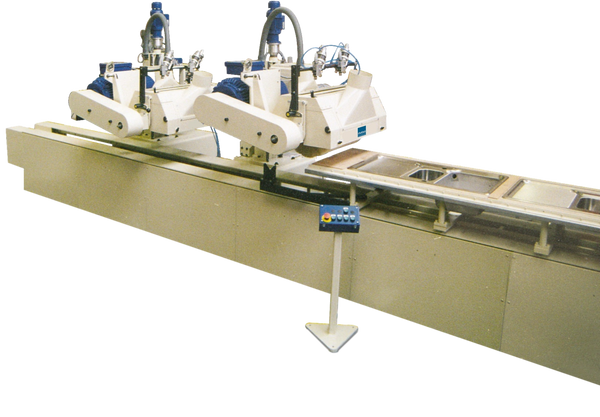

RHO Surface Polishing and Buffing Machine

PLC controlled surface polishing machine. Machine for polishing, buffing, burnishing, gloss finishing, brushing and scotching of surfaces, such as stainless-steel sinks, aluminum trim parts, wood trim parts and aluminum roof rails. The RHO is available with one or two buffing heads.

The version with two polishing units enables polishing and finishing perations in an automated sequence through the fitting of various polishing buffs. The machine features a complete protective barrier. A customer-specific suction feature can be adapted to suit the provided suction nozzle. One-axis drive of the linear table with work pieces.

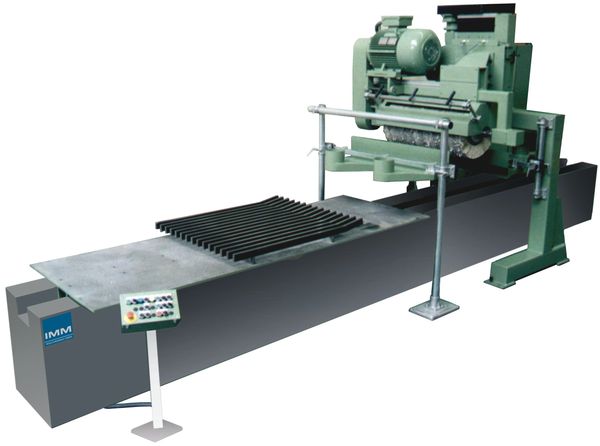

Work pieces are loaded and unloaded manually.

The machine is specifically intended for polishing the surfaces of interior and exterior automotive trim parts, the top surface of stainless-steel sinks, as roof rails or any work piece that requires a sophisticated finish. This picture shows the RHO configured for polishing shower bars of a major German manufacturer.

Integrated automated spray paste feature ensures even polishing results (optional). Cutting pace continuously adjustable through frequency onverters. Significantly reduced polishing time compared to manual processing while reaching a maximum repeatability and reproduciblity.

Precise and reproducible polishing results. Compact machine design.

Best polishing results are achieved through oscillating polishing unit(s).

The wear and tear of the polishing wheel / buff is compensated by means of a pneumatically activated pendulum arm. The machine is programmed by means of freely programmable sequencing. The RHO can also be equipped with horizontal polishing units as shown in this picture for polishing side walls of kitchen sinks.