RBG - Rotary Barrel Grinder - Cask Charring and Toasting

Cask Scraping and Skiving Machine

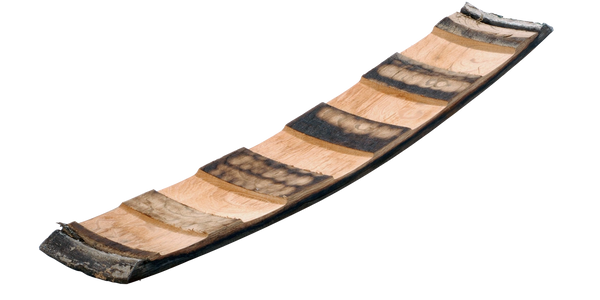

For constant material removal on the bottom and wall of all major cask types to prepare casks for cask charring and toasting. To prepare (rejuvenate) barrels and casks for cask recharring.

Machine designed for all common barrel types: American, Hog head, Sherry butt, Drum, etc.

Easy to operate machine with self teaching axis and robust Touch Screen PLC. The RBG has been designed for the roughest cooperage environment.

The RBG has been supplied to distilleries and cooperages in Scotland and Japan. It has an impeccable track record and is a most reliable process in the barrel scraping for recharring process worldwide.

Material removal is adjustable from 2 - 8 mm.

Process time for a complete cask between 6 to 10

minutes.

Cask programm creation necessary only once via Teach-In. Cask recharring made easy.

For constant material removal for cask recharring on the bottom and wall of

all major cask types: American, Hog head, Sherry butt,

Drum, etc.

Automatic compensation of tolerances on bottom

and sidewall via vertical and spindle float. Limit

switches trigger upon contact and create automatic

offset. Specially designed FESTO pneumatic control.

Various tools can be used in the RBG for preparing casks for cask recharring:

- Rasps

- Flap wheels

- Wire brushes

- Milling cutters

Once a cask is loaded for skiving to prepare for cask charring and toasting the sliding door is closed, which makes the machine completely enclosed. Dust extraction connection at the skiving/rasping head and at the machine cabinet allow for efficient extraction of wood chips and machine atmosphere (to ensure proper dilution of air inside machine to prevent alcohol mist build up). Extraction system with or without spark detection technology (GRECON) available upon request.

Work relief as cask can be rejuvenated for cask recharring as a whole without the need to take apart the cask to skive individual staves.

Easy loading as machine is lowered into prepared floor foundation. Cask is simply rolled into machine on even floor.

Easy to operate through touch-screen.

Constant quality.

Long tool life.

Tremendous cost savings in cask, barrel re-charring process.

Special operator masks for easy operation.

Interface masks allow easy generation of programs for individual cask types.