KWS - Crank shaft and rotor polishing and super-finishing

CNC grinding- and polishing machine for rotationally symmetrical work pieces. CNC polishing machine for crank shaft and rotor polishing with SIEMENS 840D controller. Machine for belt grinding, polishing and finishing of extrusion screws, large crank shafts, moineau rotors (mud motors), stator cores. 11 interpolating CNC axes guarantee a perfect positioning of the endless abrasive belt to the work piece surface and allows the processing of complex work piece geometries.

Quickly exchangeable contact wheel and slack belt attachments add to the flexibility of the KWS capability.

The cnc polishing machine can be configured, in terms of contact wheels and pulleys, to suit the work pieces intended to be processed.

The machine is controlled via 5 fully interpolating axes per belt head unit, which will be synchronized with

the work piece rotation axis. Automated processes guarantee reproducible quality. Work pieces are loaded and unloaded overhead using a crane. The IMM grinding and polishing machine KWS is designed for grinding, finishing and polishing crankshafts, barrel extruders, mud-motor rotors and feed screws with a length of up to 4500 mm (oversize available upon request up to 10,000 mm). Both belt heads can be fitted with changeable adaptors for polishing on the contact wheel, slack belt and extremely small contact wheels. This allows for the processing of radii and undercuts, and also of crank pins and journals on generator crank shafts.

The benefits of polishing crankshafts using the KWS are minimized friction and therefore a higher engine efficiency. At the same time wear, tear and crankshaft torsion and load failure is minimized. Fast cycle times – a crank shaft with a length of 3,785 mm length can be polished within 1:10 h. This includes polishing of the main, crank pin and radius areas.

The KWS is a completely enclosed cnc polishing machine with automatic sliding doors. The SIEMENS control panel is movable along the entire length of the machine.

The KWS cnc polishing machine offers high quality and a robust process through innovative finishing/polishing technology in connection with state-of-the art machine technology. Ra values of < 0.1 µm are achievable on the KWS. Conventional grinding machines only allow for a final surface finish of Ra 0.4 µm.

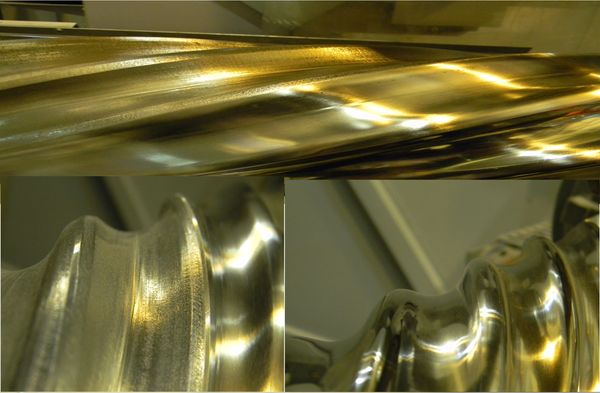

One of the many interchangeable tool units for the KWS cnc polishing machine. Whilst the crank pins and journals of a crank shaft are polished using the slack belt attachments, the unit shown here is for polishing and super-finishing the radius areas of the crank shaft and lobes of a moineau rotor (mud rotor).

Before and after examples of a 7 lobe mud motor rotor finished on the KWS cnc polishing machine (power section rotor). Perfect finish and geometry.

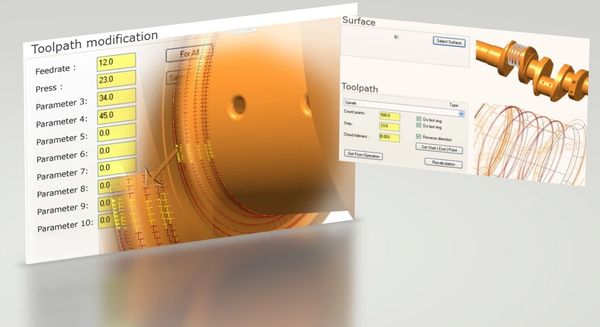

CAD/CAM software for generating NC programs for the KWS cnc polishing machine including machine simulation for collision control.

KWS cnc polishing machine videos

Check out this video on power section rotor polishing on the KWS cnc polishing machine.