KAPPA Copy Table Polisher for automotive trim

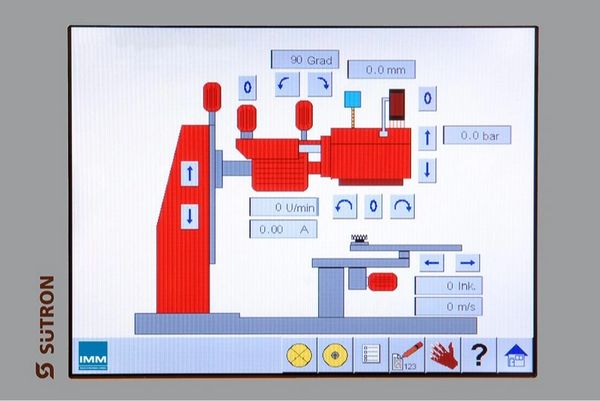

PLC controlled surface polishing machine. The new Generation of Kappa F Copy Table Polishing machine is based on many years of experience in polishing automotive trim parts.

The Kappa F is a compact design with the electrical cabinet integrated onto the machine base. This allows easy positioning of the machine. Adjustable polishing axis to enable the polishing of even the most complex shaped trim rails the new Kappa F comes with an infinitely adjustably polishing axis.

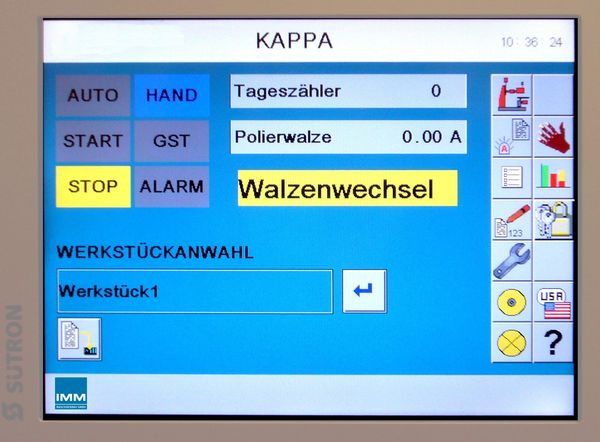

Even parts which would have required an additional manual polishing operation can now be fully automated with the all-new Kappa F. Operator Touch Panel based on an S7 controller. Operation and controlling of the machine is done via this new comfortable touch screen interface. The rpm and power of the polishing unit among further process relevant information are being displayed on the screen. All functions and operations are selected over the touch screen.

Wear compensation of the polishing buff - as the polishing buff wears down during operation an innovative and robust laser measuring device constantly measures the diameter and the controller constantly adjusts the polishing speed.

The laser device is mounted on the buff enclosure and blown off with compressed air at intervals. This ensures that the laser is kept clean. Improved positioning of the polishing compound (paste)

gun via movable mounting brackets. This ensures an effective distribution of polishing compound to the trim part and prevents increased dirt build-up at the same time. Pneumatic cylinder for the oscillation have been eliminated. This significantly reduces vibrations and hard

impacts onto the bearings and mountings. The oscillation speed is easily adjustable. Copy table driven via an internal or external drive chain.

A specially designed additional cable guiding system reduces stress on cables and hoses significantly. The cable guiding system also allows easy replacing of any cables or hoses. A floating axis ensures that the contact pressure is maintained precisely. This ensures a perfect finish for every trim part.