GAMMA RT - Engine Inlet Lip Skin Sander

Outside sander

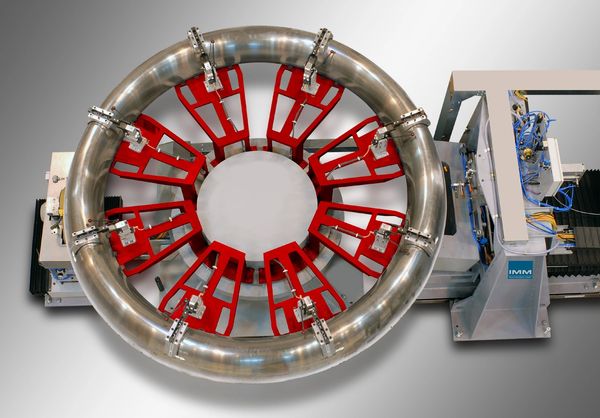

CNC engine inlet cowl lip skin sander with 3 processing heads. Machine tool with 13 CNC axis for sanding, polishing and belt grinding aircraft engine nacelle cowling. Controlled by SIEMENS 840D controller. For air inlet cowl diameters of up to 4,200 mm in diameter. Rotary table with customized fixturing system for nose cowl.

Wet grinding equipment for belt polishing using 3% coolant mixture. Machine designed for installation prepared foundation so that machine pit serves as coolant collection. Filtration by means of gravity belt filter or cyclone.

3 processing columns using counter weight balancing system. Each column is equipped with belt head for abrasive belts of 4,600 mm length. Each station to be operated with different grit for roughing, polishing and finishing aircraft engine inlet lip skins.

Each belt head is designed to travel along the entire outer contour of the aircraft engine inlet lip skin. A robust IMM designed active force control system ensures precise sanding of the entire outer surface whilst maintaining thickness tolerance. Final surface roughness achievable below Ra 0.2 mµ.

Custom made fixturing to maintain exact position and robust fit of aircraft engine inlet lip skin.

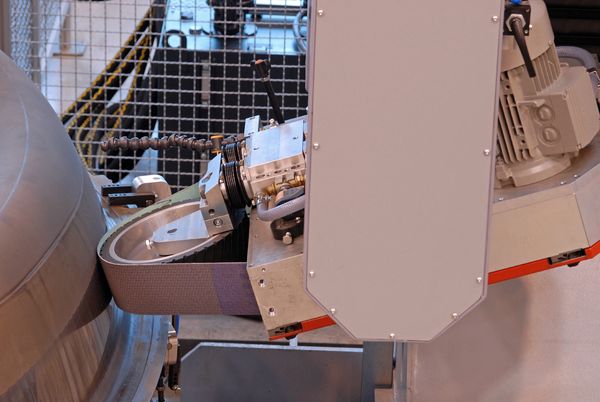

Example of installed aircraft engine inlet lip skin sander.

Inside sander for taper and edge processing

CNC aircraft engine inlet lip skin belt sander with 2 processing heads for sanding, polishing and belt grinding the edge and inside taper of the engine inlet cowl. Precise polishing force control ensures perfect tapering of the edge as well as trimming the edge to dimension.

Various surface roughness’s of taper-end achievable depending on bonding requirements, i.e. titanium with composite materials.

Edge trimming. Sanding to dimension.

Taper edge belt head and edge trimming unit.